The team uncovered a rare type of wave, known as a shear phonon polariton, in a two-dimensional form of the material. Phonon polaritons are light-matter hybrid waves that emerge when light interacts with atomic vibrations in certain crystals. They can travel through materials in unusual ways and concentrate light into extremely small volumes.

In this study, the researchers found that in thin films of gypsum, these waves undergo a topological transition, shifting from hyperbolic to elliptical behaviour, passing through a unique canalized state.

This transition allows scientists to tune how light propagates through the material.

青瓜视频淭he studies of shear phonon polaritons in previous studies were limited to bulk crystals in the hyperbolic regime. In our study we aimed to complement those initial findings with shear polaritons in a 2-dimentional material,青瓜视频� said Dr Pablo D铆az N煤帽ez, who co-led the study. 青瓜视频淎nd remarkably, we discovered that shear phonon polaritons in gypsum support a topological transition from hyperbolic to elliptical propagation, with canalization in between.青瓜视频�

Dr D铆az N煤帽ez added, 青瓜视频淢oreover, we were able to confine light to a space twenty-five times smaller than its wavelength and slow it down to just a fraction of its speed in vacuum, this opens up new possibilities for manipulating light at the nanoscale.青瓜视频�

The research also highlights the role of crystal symmetry. Gypsum belongs to a class of materials with low symmetry, specifically to the monoclinic crystal system, which gives rise to asymmetric light propagation and energy loss, the central characteristic of shear polaritons.

These findings extend beyond fundamental research of phonon polariton propagation and could support future developments in areas that rely on precise control of light, such as thermal management, sensing, and imaging beyond the limits of conventional optics. Moreover, the study introduces gypsum as a new platform for exploring advanced photonic concepts in emerging areas like non-Hermitian photonics.

This research was published in the journal .

Full title: Visualization of topological shear polaritons in gypsum thin films

DOI:

The National Graphene Institute (NGI) is a world-leading graphene and 2D material centre, focussed on fundamental research. Based at The University of Manchester, where graphene was first isolated in 2004 by Professors Sir Andre Geim and Sir Kostya Novoselov, it is home to leaders in their field 青瓜视频� a community of research specialists delivering transformative discovery. This expertise is matched by 青瓜视频13m leading-edge facilities, such as the largest class 5 and 6 cleanrooms in global academia, which gives the NGI the capabilities to advance underpinning industrial applications in key areas including: composites, functional membranes, energy, membranes for green hydrogen, ultra-high vacuum 2D materials, nanomedicine, 2D based printed electronics, and characterisation.

]]>Developed with the support of engineers at The University of Manchester since 2019, Concretene is a graphene-enhanced admixture for concrete that improves compressive strength and durability, enabling removal of cement and a reduced carbon footprint.

The company has extended its production and materials testing facility in the adjacent Pariser Building 青瓜视频� part of the new 青瓜视频� taking advantage of the advanced materials ecosystem delivered by the GEIC.

Concretene is one of several technologies being developed and applied at the GEIC to explore the potential of graphene in construction. It aims to create a more sustainable and cost-effective solution for the industry by increasing the service life of concrete and reducing cement requirements.

This is an ideal case study for 青瓜视频榯he Manchester model青瓜视频� of innovation, whereby an idea for the exploitation of nanomaterials is grown through The University of Manchester to become a spin-out company, creating high-value jobs and encouraging inward investment in the city.

Concretene has attracted 青瓜视频1.9m of UK government funding and 青瓜视频6m of venture capital investment since its incorporation in late 2022 and has grown to a staff of 20.

Three Innovate UK-funded projects have delivered significant advances in the application of graphene-enhanced concrete:

- GraphEnhance 青瓜视频� scale-up of graphene and graphene oxide supply chain (with and ).

- SMART 青瓜视频� pre-cast foundation pilings (with )

- GCRE 青瓜视频� low-carbon railway sleepers (with )

Prototype trials have demonstrated compressive strength increases up to 50% in ready-mix applications and 15-20% in pre-cast, all showing compatibility with existing low-carbon concrete mixes incorporating cement replacements (CEM II limestone, CEM III GGBS).

Tests by the Building Research Establishment (BRE) on Concretene青瓜视频檚 low-carbon railway sleeper for Cemex have indicated improvements in durability, notably to mitigate shrinkage 青瓜视频� a common problem for low-carbon concretes that can lead to cracking and shorter service life.

Collaboration is ongoing with ARUP 青瓜视频� the global design and engineering consultancy, which is one of 青瓜视频� and a range of material suppliers to hone specifications for different concrete mixes and applications, with a programme of further scaled trials upcoming to produce the robust dataset required for product certification and launch.

James Baker, CEO of Graphene@Manchester, said:

青瓜视频淲e青瓜视频檙e incredibly proud to support Concretene青瓜视频檚 journey as a standout example of how graphene innovation at the GEIC can scale into real-world industrial impact. Their progress reflects the strength of our collaborative model, which brings together engineers, researchers and industry to tackle global challenges like decarbonising construction. Concretene represents the kind of transformative work we青瓜视频檙e driving forward, and we continue to collaborate with a broad range of partners to accelerate the adoption of graphene-enhanced technologies that deliver both environmental and economic benefits.青瓜视频�

Mike Harrison, CEO of Concretene, said:

青瓜视频淲e青瓜视频檙e really pleased to extend our deal with the GEIC for another three years. Having a dedicated formulation development facility, technical support and high-end microscopy and characterisation kit on site has been invaluable in the development of the product. The proximity of growth and maker space within the Sister Innovation District has allowed us to remain in Manchester and we are grateful of the support from this community.

青瓜视频淲e look forward to building on our success to date with the GEIC, commissioning our pilot plant in the Pariser Building and supporting asset owners in their journey to decarbonise concrete in construction.青瓜视频�

Advanced materials is one of The University of Manchester青瓜视频檚 research beacons - examples of pioneering discoveries, interdisciplinary collaboration and cross-sector partnerships tackling some of the planet's biggest questions. #ResearchBeacons

]]>Desalination of seawater and brackish water is one of the essential solutions to the increasing global challenge of water scarcity. Yet, widespread deployment of desalination technologies remains limited due to high upfront costs and intensive energy requirements. Moreover, current desalination systems use fossil fuels contributing to greenhouse gas emissions.

To address these challenges, the EU-funded project AQUASOL brings together a multidisciplinary team of seven partners from six countries to explore and develop innovative solutions to facilitate green transition in desalination processes. To achieve this, the consortium will develop a technological platform that will enable the integration of renewable energy sources into desalination technologies and provide disruptive solutions for seawater and wastewater treatment.

, a researcher at Manchester, will develop graphene-based membranes designed to treat seawater and brackish water more efficiently. The goal is to increase membrane durability and reduce energy demands, offering practical improvements over current desalination systems.

The partners, comprising of research institutions, universities and small and medium businesses, met in Barcelona to officially launch the project, which started earlier this month.

AQUASOL, which stands for Advanced Quality Renewable Energy-Powered Solutions For Water Desalination In Agriculture And Wastewater Recycling, has a total budget of over 鈧�3.6M and will run for 3 years. The University of Manchester joins six other partners: Instituto Tecnol贸gico de Canarias (Spain), Strane Innovation (France), Ferr-Tech B.V. (Netherlands), farmB (Greece), and Aarhus University (Denmark).

Acknowledgements

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency (REA). Neither the European Union nor the granting authority can be held responsible for them.

We青瓜视频檙e home to 700 materials experts, revolutionising industries by developing advanced materials that unlock new levels of performance, efficiency, and sustainability. Supported by the 青瓜视频885m campus investment over the last 10 years, our researchers are at the forefront of materials innovation, creating game-changing solutions. From healthcare to manufacturing, we青瓜视频檙e tackling global challenges and ensuring the UK's reputation as a technology 青瓜视频榮uper power'. Find out more about our advanced materials research.

]]>The team designed a two-dimensional (2D) manganese-oxide/graphene superlattice that triggers a unique lattice-wide strain mechanism. This approach significantly boosts the structural stability of the battery青瓜视频檚 cathode material, enabling it to operate reliably over 5,000 charge-discharge cycles. That青瓜视频檚 around 50% longer than current zinc-ion batteries.

The research, published in , offers a practical route to scalable, water-based energy storage technologies.

]]>The team designed a two-dimensional (2D) manganese-oxide/graphene superlattice that triggers a unique lattice-wide strain mechanism. This approach significantly boosts the structural stability of the battery青瓜视频檚 cathode material, enabling it to operate reliably over 5,000 charge-discharge cycles. That青瓜视频檚 around 50% longer than current zinc-ion batteries.

The research, published in , offers a practical route to scalable, water-based energy storage technologies.

Atomic-level control over battery durability

The breakthrough centres on a phenomenon called the Cooperative Jahn-Teller Effect (CJTE). A coordinated lattice distortion caused by a specific 1:1 ratio of manganese ions (Mn鲁鈦� and Mn鈦粹伜). When built into a layered 2D structure on graphene, this ratio produces long-range, uniform strain across the material.

That strain helps the cathode resist breakdown during repeated cycling.

The result is a low-cost, aqueous zinc-ion battery that performs with greater durability, and without the safety risks linked to lithium-ion cells.

青瓜视频淭his work demonstrates how 2D material heterostructures can be engineered for scalable applications,青瓜视频� said , lead and corresponding author from University of Technology Sydney and a Royal Society Wolfson visiting Fellow at The University of Manchester. 青瓜视频淥ur approach shows that superlattice design is not just a lab-scale novelty, but a viable route to improving real-world devices such as rechargeable batteries. It highlights how 2D material innovation can be translated into practical technologies.青瓜视频�

Towards better grid-scale storage

Zinc-ion batteries are widely viewed as a promising candidate for stationary storage, storing renewable energy for homes, businesses or the power grid. But until now, their limited lifespan has restricted real-world use.

This study shows how chemical control at the atomic level can overcome that barrier.

Co-corresponding author from The University of Manchester said, 青瓜视频淥ur research opens a new frontier in strain engineering for 2D materials. By inducing the cooperative Jahn-Teller effect, we青瓜视频檝e shown that it青瓜视频檚 possible to fine-tune the magnetic, mechanical, and optical properties of materials in ways that were previously not feasible.青瓜视频�

The team also demonstrated that their synthesis process works at scale using water-based methods, without toxic solvents or extreme temperatures - a step forward in making zinc-ion batteries more practical for manufacturing.

This research was published in the journal Nature Communications.

Full title: Cooperative Jahn-Teller effect and engineered long-range strain in manganese oxide/graphene superlattice for aqueous zinc-ion batteries

DOI:

We青瓜视频檙e home to 700 materials experts, revolutionising industries by developing advanced materials that unlock new levels of performance, efficiency, and sustainability. Supported by the 青瓜视频885m campus investment over the last 10 years, our researchers are at the forefront of materials innovation, creating game-changing solutions. From healthcare to manufacturing, we青瓜视频檙e tackling global challenges and ensuring the UK's reputation as a technology 青瓜视频榮uper power'. Find out more about our advanced materials research.

The is a world-leading graphene and 2D material centre, focussed on fundamental research. Based at The University of Manchester, where graphene was first isolated in 2004 by Professors Sir Andre Geim and Sir Kostya Novoselov, it is home to leaders in their field 青瓜视频� a community of research specialists delivering transformative discovery. This expertise is matched by 青瓜视频13m leading-edge facilities, such as the largest class 5 and 6 cleanrooms in global academia, which gives the NGI the capabilities to advance underpinning industrial applications in key areas including: composites, functional membranes, energy, membranes for green hydrogen, ultra-high vacuum 2D materials, nanomedicine, 2D based printed electronics, and characterisation.

]]>The results have been published in the journal .

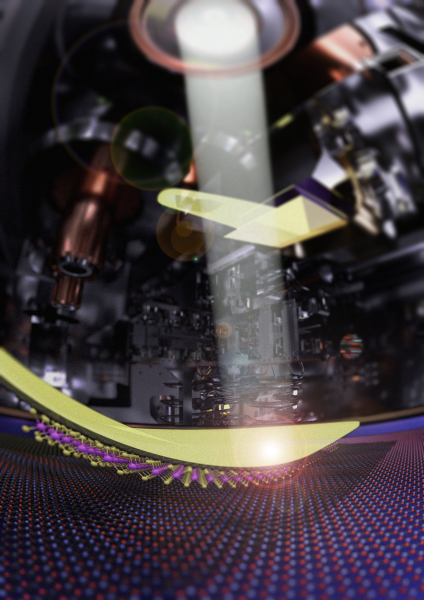

Using a new two-step fabrication method, the researchers demonstrated for the first time that it is possible to create and monitor, 青瓜视频榓s they switch on青瓜视频�, individual Group-IV quantum defects in diamond青瓜视频攖iny imperfections in the diamond crystal lattice that can store and transmit information using the exotic rules of quantum physics. By carefully placing single tin atoms into synthetic diamond crystals and then using an ultrafast laser to activate them, the team achieved pinpoint control over where and how these quantum features appear. This level of precision is vital for making practical, large-scale quantum networks capable of ultra-secure communication and distributed quantum computing to tackle currently unsolvable problems.

Study co-author , Department of Materials at the University of Oxford, said: 青瓜视频淭his breakthrough gives us unprecedented control over single tin-vacancy colour centres in diamond, a crucial milestone for scalable quantum devices. What excites me most is that we can watch, in real time, how the quantum defects are formed.青瓜视频�

Specifically, the defects in the diamond act as spin-photon interfaces, which means they can connect quantum bits of information (stored in the spin of an electron) with particles of light. The tin-vacancy defects belong to a family known as Group-IV colour centres青瓜视频攁 class of defects in diamond created by atoms such as silicon, germanium, or tin.

Group-IV centres have long been prized for their high degree of symmetry, which gives them stable optical and spin properties, making them ideal for quantum networking applications. It is widely thought that tin-vacancy centres have the best combination of these properties青瓜视频攂ut until now, reliably placing and activating individual defects was a major challenge.

The researchers used a focused ion beam platform青瓜视频攅ssentially a tool that acts like an atomic-scale spray can, directing individual tin ions into exact positions within the diamond. This allowed them to implant the tin atoms with nanometre accuracy青瓜视频攆ar finer than the width of a human hair.

To convert the implanted tin atoms to tin-vacancy colour centres, the team then used ultrafast laser pulses in a process called laser annealing. This process gently excites tiny regions of the diamond without damaging it. What made this approach unique was the addition of real-time spectral feedback青瓜视频攎onitoring the light coming from the defects during the laser process. This allowed the scientists to see in real time when a quantum defect became active and adjust the laser accordingly, offering an unprecedented level of control over the creation of these delicate quantum systems.

Study co-author from the University of Cambridge, said: 青瓜视频淲hat is particularly remarkable about this method is that it enables in-situ control and feedback during the defect creation process. This means we can activate quantum emitters efficiently and with high spatial precision - an important tool for the creation of large-scale quantum networks. Even better, this approach is not limited to diamond; it is a versatile platform that could be adapted to other wide-bandgap materials.青瓜视频�

Moreover, the researchers observed and manipulated a previously elusive defect complex, termed 青瓜视频淭ype II Sn青瓜视频�, providing a deeper understanding of defect dynamics and formation pathways in diamond.

Study co-author , Professor of Advanced Electronic Materials at The University of Manchester, said: 青瓜视频淭his work unlocks the ability to create quantum objects on demand, using methods that are reproducible and can be scaled up. This is a critical step in being able to deliver quantum devices and allow this technology to be utilised in real-world commercial applications.青瓜视频�

The study 青瓜视频楲aser Activation of Single Group-IV Colour Centres in Diamond青瓜视频� has been published in Nature Communications:

]]>Researchers at The University of Manchester have developed a ground-breaking method to precisely measure the strength of hydrogen bonds in confined water systems, an advance that could transform our understanding of water青瓜视频檚 role in biology, materials science, and technology. The work, published in , introduces a fundamentally new way to think about one of nature青瓜视频檚 most important but difficult-to-quantify interactions.

]]>Researchers at The University of Manchester have developed a ground-breaking method to precisely measure the strength of hydrogen bonds in confined water systems, an advance that could transform our understanding of water青瓜视频檚 role in biology, materials science, and technology. The work, published in , introduces a fundamentally new way to think about one of nature青瓜视频檚 most important but difficult-to-quantify interactions.

Hydrogen bonds are the invisible forces that hold water molecules together, giving water its unique properties, from high boiling point to surface tension, and enabling critical biological functions such as protein folding and DNA structure. Yet despite their significance, quantifying hydrogen bonds in complex or confined environments has long been a challenge.

青瓜视频淔or decades, scientists have struggled to measure hydrogen bond strength with precision,青瓜视频� said , who led the study with and Dr Ziwei Wang. 青瓜视频淥ur approach reframes hydrogen bonds as electrostatic interactions between dipoles and an electric field, which allows us to calculate their strength directly from spectroscopic data.青瓜视频�

The team used gypsum (CaSO鈧劼�2H鈧侽), a naturally occurring mineral that contains two-dimensional layers of crystalline water, as their model system. By applying external electric fields to water molecules trapped between the mineral青瓜视频檚 layers, and tracking their vibrational response using high-resolution spectroscopy, the researchers were able to quantify hydrogen bonding with unprecedented accuracy.

青瓜视频淲hat青瓜视频檚 most exciting is the predictive power of this technique,青瓜视频� said Dr Yang. 青瓜视频淲ith a simple spectroscopic measurement, we can predict how water behaves in confined environments that were previously difficult to probe, something that normally requires complex simulations or remains entirely inaccessible.青瓜视频�

The implications are broad and compelling. In water purification, this method could help engineers fine-tune membrane materials to optimise hydrogen bonding, improving water flow and selectivity while reducing energy costs. In drug development, it offers a way to predict how water binds to molecules and their targets, potentially accelerating the design of more soluble and effective drugs. It could enhance climate models by enabling more accurate simulations of water青瓜视频檚 phase transitions in clouds and the atmosphere. In energy storage, the discovery lays the foundation for 青瓜视频渉ydrogen bond heterostructures青瓜视频�, engineered materials with tailored hydrogen bonding that could dramatically boost battery performance. And in biomedicine, the findings could help create implantable sensors with better compatibility and longer lifespans by precisely controlling water-surface interactions.

青瓜视频淥ur work provides a framework to understand and manipulate hydrogen bonding in ways that weren青瓜视频檛 possible before,青瓜视频� said Dr Wang, first author of the paper. 青瓜视频泪迟 opens the door to designing new materials and technologies, from better catalysts to smarter membranes, based on the hidden physics of water.青瓜视频�

This research was published in the journal Nature Communications.

Full title: Quantifying hydrogen bonding using electrically tunable nanoconfined water

DOI:

The research was supported by the European Research Council and UK Research and Innovation (UKRI).

The is a world-leading graphene and 2D material centre, focussed on fundamental research. Based at The University of Manchester, where graphene was first isolated in 2004 by Professors Sir Andre Geim and Sir Kostya Novoselov, it is home to leaders in their field 青瓜视频� a community of research specialists delivering transformative discovery. This expertise is matched by 青瓜视频13m leading-edge facilities, such as the largest class 5 and 6 cleanrooms in global academia, which gives the NGI the capabilities to advance underpinning industrial applications in key areas including: composites, functional membranes, energy, membranes for green hydrogen, ultra-high vacuum 2D materials, nanomedicine, 2D based printed electronics, and characterisation.

]]>R2I is a bespoke entrepreneurship training programme for late stage PhD students, PDRAs and early-career researchers from across all faculties with ambitions to develop commercial ventures or to create impact from their research. The programme includes a series of interactive personal and professional development sessions, which introduce the concept of commercialisation, equipping researchers with strategies to take ideas forward and discover new pathways to funding.

Read more about the researchers recently supported to further their ideas.

Key Dates:

- Application Deadline: 23:59, 8th April 2025 []

- Boot Camp Day 1: Monday 28th April 2025

- Boot Camp Day 2: Thursday 8th May 2025

- Full Programme: Monday 28th April 青瓜视频� Thursday 17th July 2025

Don青瓜视频檛 miss the opportunity to be part of the next cohort and join a network of likeminded researchers.

to secure your place on the programme!

To find out more about the R2I Programme visit our

The MEC Researcher to Innovator (R2I) programme is supported by the University青瓜视频檚 Innovation Academy. The Innovation Academy is a pan University initiative and joint venture between the , the and the Business Engagement and Knowledge Exchange team, bringing together knowledge, expertise and routes to facilitate the commercialisation of research.

The breakthrough centres around an active spatial light modulator, a surface with more than 300,000 sub-wavelength pixels capable of manipulating THz light in both transmission and reflection. Unlike previous modulators, which were limited to small-scale demonstrations, the Manchester team integrated graphene-based THz modulators with large-area thin-film transistor (TFT) arrays, enabling high-speed, programmable control over the amplitude and phase of THz light across expansive areas.

, Professor of 2D Device Materials at The University of Manchester, commented, 青瓜视频淲e have developed a new method to dynamically control THz waves at an unprecedented scale and speed. By integrating graphene optoelectronics with advanced TFT display technologies, we can now reconfigure complex THz wavefronts in real time.青瓜视频�

The research demonstrates various capabilities, including programmable THz transmission patterns, beam steering, greyscale holography, and a proof-of-concept single-pixel THz camera. These functionalities are made possible through fine-tuned electrostatic gating of graphene, a material known for its unique electrical and optical properties at THz frequencies.

Co-author Dr M. Said Ergoktas, now a lecturer at the University of Bath, added, 青瓜视频淥ur devices operate by adjusting local charge densities on a continuous graphene sheet, allowing for pixel-level control without the need for graphene patterning. This architecture allows for scalable fabrication using commercial display backplanes.青瓜视频�

The team青瓜视频檚 device architecture also supports dynamic beam steering and the generation of structured THz beams carrying orbital angular momentum, key features for advanced THz communication systems. One striking demonstration showed how a binary 青瓜视频渇ork青瓜视频� diffraction pattern generated donut-shaped beams with tunable vortex order, useful in multiplexed data transmission and beam shaping.

Beyond communications, the researchers showcased a single-pixel THz camera capable of imaging concealed metallic objects, representing a significant advance for non-invasive inspection in security, industrial monitoring, and medical diagnostics. This approach uses compressive sensing algorithms to reconstruct images from modulated THz patterns, highlighting the flexibility of their programmable platform.

青瓜视频淯ntil now, THz modulators have struggled with scale and speed,青瓜视频� Kocabas noted. 青瓜视频淏y leveraging display technology, we demonstrate that it's possible to bring this field from lab-scale demonstrations to real-world applications.青瓜视频�

Future directions

The authors indicate that the next steps involve enhancing modulation speeds and extending these systems to operate in reflection mode for full spectroscopic imaging. Future work may also focus on integrating this platform with advanced beamforming systems and next-generation 6G wireless technologies.

The is a world-leading graphene and 2D material centre, focussed on fundamental research. Based at The University of Manchester, where graphene was first isolated in 2004 by Professors Sir Andre Geim and Sir Kostya Novoselov, it is home to leaders in their field 青瓜视频� a community of research specialists delivering transformative discovery. This expertise is matched by 青瓜视频13m leading-edge facilities, such as the largest class 5 and 6 cleanrooms in global academia, which gives the NGI the capabilities to advance underpinning industrial applications in key areas including: composites, functional membranes, energy, membranes for green hydrogen, ultra-high vacuum 2D materials, nanomedicine, 2D based printed electronics, and characterisation.

]]>Lignin 青瓜视频� a widely available by-product of cellulose production, with around 70 million tonnes generated annually 青瓜视频� offers a promising, sustainable alternative. Typically treated as waste or burned for energy, lignin has untapped potential for high-value applications, including next-generation carbon fibre manufacturing.

From lab to pilot scale

Industry partner Lixea has been collaborating with Imperial College London, where Dr Agi Brandt-Talbot and Professor Milo Shaffer developed a patented technology to convert lignin into carbon fibre at a small lab scale (1ml production). The process leveraged two key innovations:

- Ionic liquid technology 青瓜视频� dissolving various lignins while allowing the liquid to be recycled after fibre formation.

- Polyvinyl alcohol (PVA) 青瓜视频� a non-toxic, biodegradable polymer used as a spinning aid.

This approach not only enables the production of high-lignin-content fibres (75-90%) with excellent structure and yield but also significantly reduces costs. By replacing petroleum-based precursors with lignin and ionic liquids 青瓜视频� both renewable, lower-cost, and less toxic materials 青瓜视频� production costs could be reduced.

Manchester青瓜视频檚 ability to scale up

To validate this technology at scale, Dr Joanne Ng from Imperial College joined forces with Drs Dominic Wales and Umar Muhammad, researchers at The University of Manchester and Royce Application Scientists, led by . Together the team created a pilot-scale demonstration at the Fibre Technology Platform, at the Henry Royce Institute, using its wet spinning line. Lignin was sourced from Lixea青瓜视频檚 pilot plant, which uses the same ionic liquid to extract lignin from wood waste, ensuring process alignment with the company青瓜视频檚 existing technologies.

The team tested three different lignins 青瓜视频� two from spruce sawdust, and one from bagasse, a by-product of sugar production 青瓜视频� with the bagasse-derived lignin proving most effective, enabling continuous fibre spinning at pilot scale for the first time.

Key learning and future development

Several critical insights emerged from the trials. Firstly, drying control was crucial to prevent fibre shrinkage. Secondly, lignin solutions became more viscous over time, requiring adjustments to maintain quality. And thirdly, spinneret design affected fibre uniformity, highlighting the need for further refinement and development of the facility.

Through the project the team successfully produced continuous fibres. The next steps include refining fibre drying, collection, and carbonisation processes, which will be essential for scaling up this breakthrough technology in the UK.

A milestone for sustainable carbon fibre

Manchester青瓜视频檚 success in scaling up this novel technology marks a significant step toward commercially viable, sustainable carbon fibre production.

The future of carbon fibre innovation

With continued advancements and industry collaboration, lignin-based carbon fibre could soon become a commercially scalable, high-performance, and environmentally friendly alternative to petroleum-derived materials. Manchester青瓜视频檚 pioneering role in technology scale-up reinforces its position as a leader in materials innovation and sustainable manufacturing, helping new ideas emerging in other UK leading universities, such as Imperial, make real-world impact.

Meet the researcher

Jonny Blaker, Professor in Biomaterials, principle research areas are i) Bio-inspired hierarchical composite materials and ii) Advanced materials derived from synthetic biology, with an emphasis on medical applications. He currently leads projects on bioactive medical materials, mask-less digital photolithography for 3D printing/patterning surfaces, development of bio-inks for 3D printing/biofabrication, the exploitation surfaces and interfaces for materials production, processing of fibres, especially nanofibres via solution blow spinning including silks derived from synthetic biology, as well as shape-morphing composites.

We青瓜视频檙e home to 700 materials experts, revolutionising industries by developing advanced materials that unlock new levels of performance, efficiency, and sustainability. Supported by the 青瓜视频885m campus investment over the last 10 years, our researchers are at the forefront of materials innovation, creating game-changing solutions. From healthcare to manufacturing, we青瓜视频檙e tackling global challenges and ensuring the UK's reputation as a technology 青瓜视频榮uper power'. Find out more about our advanced materials research.

]]>Congratulations to CDT student Patrick Sarsfield, winner of the 青瓜视频20,000 second prize with co-founder of Graphene Thermal Daniel Mills. Patrick is currently doing his PhD in the Theory of Electronic Properties of Graphene.

Manchester青瓜视频檚 reputation as a global leader in graphene innovation was reinforced as (MEC) announced the winners of the 2025 Eli & Britt Harari Graphene Enterprise Award. The prestigious competition, which supports students, postgraduates, and recent alumni in turning cutting-edge research into viable businesses, awarded 青瓜视频50,000 and 青瓜视频20,000 to two outstanding ventures set to disrupt industries with their graphene and 2D material-based technologies.

The grand final, held on March 11 2025, saw finalists pitch their groundbreaking ideas to an expert panel at Alliance Manchester Business School. The event culminated in a hybrid awards ceremony at the Enterprise Zone, with a global audience tuning in via livestream. Keynotes from Aurore Hochard, Director of MEC, and Luke Georghiou, Deputy President and Deputy Vice-Chancellor, highlighted the University青瓜视频檚 commitment to turning research into real-world solutions. A fireside chat with last year青瓜视频檚 winners, Solar Ethos, provided valuable insights for the next generation of graphene entrepreneurs.

The panel featured distinguished leaders in entrepreneurship and graphene innovation at The University of Manchester. The group included Aurore Hochard, James Baker (CEO of Graphene@Manchester), Professor Luke Georghiou, Dr. Ania Jolly (Henry Royce Institute), Professor Aravind Vijayaraghavan (founder of Grafine Ltd.), and Dr. Vivek Koncherry (CEO of Graphene Innovations Manchester). Their expertise ensured a rigorous selection process, identifying businesses with the strongest potential for commercial success.

The four finalists for this year showcased diverse and innovative applications of graphene and 2D materials.

- Patrick Johansen Sarsfield from the School of Natural Sciences is developing Graphene Thermal - a company creating efficient graphene heated floor panels that reach target temperatures rapidly while using 50% less power than competitors.

- Jorge Servert from the School of Biological Sciences leads Sensium, which is revolutionising molecular diagnostics. Their technology achieves 90-95% accuracy in detecting various conditions, including infections and STIs, in under 5 minutes at just $1 per test.

- Mohammadhossein Saberian from the School of Natural Sciences heads Metamorph Materials, which transforms biomass into carbon-negative graphite for lithium-ion batteries, offering a sustainable alternative that enhances battery performance for EVs and electronics.

- Rui Zhang from the School of Natural Sciences presents Graphene Vision, developing next-generation in-situ cells that enhance materials characterisation systems. Their cost-effective solution enables real-time atomic-level imaging, accelerating research in various fields including catalysis and biomaterials.

The 青瓜视频50,000 first prize was awarded to Jorge A. Servert of Sensium (School of Biological Sciences), who combines expertise from diagnostics with his PhD in Biophysics. Jorge was also part of MEC青瓜视频檚 Researcher to Innovator (R2I) programme where he received support in delivering impact with his research.

The 青瓜视频20,000 second prize went to Patrick Johansen Sarsfield of Graphene Thermal with co-founder Daniel Mills, aircraft engineer at General Aero Services. Patrick is currently doing his PhD in the Theory of Electronic Properties of Graphene. We also extend recognition to finalists Mohammadhossein Saberian (School of Natural Sciences) of Metamorph Materials, and Rui Zhang (School of Natural Sciences) of Graphene Vision. Rui was part of MEC青瓜视频檚 Researcher to Innovator (R2I) programme where he received support in delivering impact with his research.

We congratulate all participants on their outstanding achievements. Their innovations hold tremendous potential for commercial impact, from sustainable materials to next-generation electronics. By supporting these enterprising individuals, The University of Manchester is not only fostering personal success but also driving forward solutions to global challenges.

青瓜视频淭o everyone, the journey continues and it's all about resilience青瓜视频� - Aurore Hochard, Director of the Masood Entrepreneurship Centre.

The chances of a dental appointment resulting in an antibiotic prescription increased dramatically during the pandemic, and new led by Dr Wendy Thompson from The University of Manchester shows prescribing levels across each of the UK青瓜视频檚 four nations have been slow to return to where they would have been if the pandemic hadn青瓜视频檛 happened.

Though the Government has begun commissioning 700,000 urgent appointments, the British Dental Association says the total unmet need is far higher.

Dr Thompson also leads on antimicrobial stewardship for the College of General Dentistry and chairs the FDI World Dental Federation's Preventing Antimicrobial Resistance (AMR) and Infections task team.

She said: 青瓜视频淭oo many people have been unable to access urgent dental treatment for toothache, and have ended up with antibiotics. The best way to protect us all from the existential threat of antibiotic resistance is to ensure patients have timely access to urgent care.

青瓜视频淓ven before the COVID-19 pandemic, we knew that dentistry was responsible for around 10% of antibiotic prescriptions and that rates of unnecessary use were high. During the early part of the COVID-19 pandemic, the amount of antibiotic prescribing by NHS dentists

青瓜视频淥ur research has shown how were at this situation which UK Health Security Agency researchers have linked to the use of , where care is given remotely. Our latest shows just how slowly antibiotic prescribing in NHS dentistry is returning to its pre-pandemic pattern.

青瓜视频淎ntibiotics don't cure toothache although our research shows that many people wrongly believe they are necessary. Unnecessary use puts patients and the public at risk from the spread of infections which don't respond to antibiotics. The for toothache and dental infections is generally a procedure rather than a prescription, although sometimes antibiotics are vital. found that appointments where dentists provide procedures take more time than just giving antibiotics.青瓜视频�

青瓜视频淭hat is why FDI World Dental Federation argues that to the right oral health care at the right time to prevent and treat toothache and dental infection should be an essential part of national efforts to tackle antimicrobial resistance by reducing the unnecessary use of antibiotics.青瓜视频�

She added: 青瓜视频淩outine monitoring of antibiotic prescribing by dentists providing care to NHS patients is key, but until prescribing by dentists is digitised, this will be impossible. Integrating high-street dentistry into NHS digital systems will be an important part of national efforts to help keep patients safe by ensuring antibiotics are only prescribed when strictly necessary.青瓜视频�

]]>This renewed collaboration is a key pillar of GIM青瓜视频檚 青瓜视频250 million expansion strategy, reinforcing the UK as a leading hub for research, innovation, and advanced materials. As part of this ambitious plan, the initiative is expected to create over 1,000 skilled jobs in the UK青瓜视频攁n impact highlighted recently by British Prime Minister Sir Keir Starmer.

GIM, a spin-out from The University of Manchester and GEIC, was formed through our unique Bridging the Gap programme, designed to help start-ups and SMEs commercialise cutting-edge graphene technologies. Since then, GIM has been at the forefront of rapid graphene-based commercial product development, pioneering sustainable building materials and next-generation Artificial Intelligence (AI) based manufacturing delivering global impact.

Notably, GIM has launched the world青瓜视频檚 first commercial production of graphene-enriched carbon fibre in the Kingdom of Saudi Arabia青瓜视频攁 game-changing step in scaling up graphene-based technologies to reduce global CO鈧� emissions and diversify the hydrocarbon economy.

James Baker, CEO of Graphene@Manchester:

"GIM's commitment to innovation and sustainability exemplifies the transformative potential of graphene. Their continued partnership with GEIC not only accelerates technological advancements but also brings substantial economic benefits to Greater Manchester. Great to have them on board, and we青瓜视频檙e excited for what青瓜视频檚 ahead."

Dr Vivek Koncherry, CEO & Chairman of GIM:

"Extending our partnership with the GEIC is pivotal for our mission to drive large-scale manufacturing of sustainable graphene-enhanced products both in the UK and globally as well as creating multiple Unicorn companies. This collaboration enables us to tap into world-class resources and expertise within the graphene ecosystem, pushing us much closer to our vision of a truly sustainable and profitable future, leading the Graphene Age."

This extended partnership strengthens Manchester青瓜视频檚 reputation as the Home of Graphene, ensuring continued innovation, collaboration, and real-world impact through world-leading research and industry partnerships.

For more details on the UK government青瓜视频檚 announcement, .

The GEIC operates a partnership model, offering a variety of engagement options tailored to the scope, scale, duration and complexity of development projects. for more information and to get in touch.

]]>Innovative approach to spintronics

Spin transport electronics, or spintronics, represents a revolutionary alternative to traditional electronics by utilising the spin of electrons rather than their charge to transfer and store information. This method promises energy-efficient and high-speed solutions that exceed the limitations of classical computation, for next generation classical and quantum computation.

The Manchester team, led by , has fully encapsulated monolayer graphene in hexagonal boron nitride, an insulating and atomically flat 2D material, to protect its high quality. By engineering the 2D material stack to expose only the edges of graphene, and laying magnetic nanowire electrodes over the stack, they successfully form one-dimensional (1D) contacts.

Quantum behaviour and ballistic transport

The study explores the injection process via these 1D contacts at low temperatures (20 K), revealing that electron transport across the interface is quantum in nature. The contacts act as quantum point contacts (QPCs), commonly used in quantum nanotechnology and metrology.

First author of the paper, Dr Daniel Burrow, said 青瓜视频渢his quantum behaviour is evidenced by the measurement of quantised conductance through the contacts, indicating that the energy spectrum of electrons transforms into discrete energy subbands upon injection. By adjusting the electron density in the graphene and applying a magnetic field, we visualised these subbands and explored their connection with spin transport.青瓜视频�

These QPCs, formed by using magnetic nanowires, avoid the need to engineer a physical constriction within the graphene channel, which makes their implementation more practical than previous approaches.

Implications for quantum nanotechnology

The state-of-the-art device architecture developed by the Manchester team offers a straightforward method for creating tuneable QPCs in graphene, overcoming fabrication challenges associated with other methods. The magnetic nature of the nanoscale contacts enables quantised spin injection, paving the way for energy-efficient devices in spin-based quantum nanotechnology.

Furthermore, the demonstration of ballistic spin injection presents an encouraging step towards the development of low-power ballistic spintronics. Future research efforts will focus on enhancing spin transport in graphene by leveraging the quantum nature of injection via the QPCs.

This research is part of the Horizon Europe Project "2D Heterostructure Non-volatile Spin Memory Technology" (2DSPIN-TECH), supported by a UKRI grant.

We青瓜视频檙e home to 700 materials experts, revolutionising industries by developing advanced materials that unlock new levels of performance, efficiency, and sustainability. Supported by the 青瓜视频885m campus investment over the last 10 years, our researchers are at the forefront of materials innovation, creating game-changing solutions. From healthcare to manufacturing, we青瓜视频檙e tackling global challenges and ensuring the UK's reputation as a technology 青瓜视频榮uper power'. Find out more about our advanced materials research.

The is a world-leading graphene and 2D material centre, focussed on fundamental research. Based at The University of Manchester, where graphene was first isolated in 2004 by Professors Sir Andre Geim and Sir Kostya Novoselov, it is home to leaders in their field 青瓜视频� a community of research specialists delivering transformative discovery. This expertise is matched by 青瓜视频13m leading-edge facilities, such as the largest class 5 and 6 cleanrooms in global academia, which gives the NGI the capabilities to advance underpinning industrial applications in key areas including: composites, functional membranes, energy, membranes for green hydrogen, ultra-high vacuum 2D materials, nanomedicine, 2D based printed electronics, and characterisation.

]]>This award serves as more than just a recognition; it acts as seed funding, providing the awarded candidate with the necessary financial support to take the first crucial steps towards realizing their ambitious plan. It acknowledges the pivotal role that flexible, early-stage financial backing can play in the successful development and growth of a business, particularly one that aims for the full commercialisation of a product or technology related to ground-breaking research in graphene.

The deadline for applications is Monday, 10 February 2025 (Midday)

Applications are welcomed from students, postdoctoral researchers, and recent graduates of The University of Manchester.

- For further details please go to | | The University of Manchester

- For any further information or queries, please contact: elibrittharariaward@manchester.ac.uk

Announced today, the research programme aims to address the challenges of plastic waste in healthcare settings by exploring the relationship between social practice, material selection, reuse, and recycling while maintaining high-quality clinical outcomes. In response to complex sustainability challenges in the sector, the work will explore circular pathways, identify barriers and unintended consequences, and unlock opportunities to minimise the environmental impacts of materials in healthcare settings.

The three-year partnership brings together two organisations striving for authentic environmental sustainability, backed by innovative research and real-world practice. The collaboration is co-funded by an EPSRC Prosperity Partnership award, UKRI青瓜视频檚 flagship co-investing programme building business and academic research collaboration.

Professor Mike Shaver, Director of Sustainable Futures and academic lead for the new partnership said: 青瓜视频淲e are thrilled by the opportunity to work with Bupa on this ambitious new project, extending our systemic understanding of plastics, waste management, social practice and environmental impacts to reshape material provision in healthcare. These collaborations are essential to translating our research efforts into real world impact.青瓜视频�

A key challenge for a sustainable future is the way we use and dispose of materials. Over 60% of countries have implemented bans or taxes on household waste, particularly plastics, yet healthcare is much more complex. The sector青瓜视频檚 reliance on single-use items (SUIs) for infection control, consistency, and cost efficiency has led to significant environmental and health challenges, with SUIs contributing to carbon emissions, waste, and plastic pollution.

The crucial new interdisciplinary collaboration will tackle four key urgent areas:

- Understanding social practice in medical practices - Understand the interconnectedness between social practice and material selection, use, segregation and disposal.

- Reuse and sterility - Understand the relationship between material selection, sterilisation and reuse to improve environmental sustainability

- Mechanical and chemical recycling - Establish high volume clinical waste streams to create value in mechanical recycling and chemical depolymerization.

- Environmental sustainability assessment - Quantify environmental impacts and develop materials hierarchies in the provision of healthcare.

Anna Russell, Director of Sustainability and Corporate Responsibility, Bupa, said: 青瓜视频淭his partnership with The University of Manchester is groundbreaking for our sector. Tackling healthcare青瓜视频檚 environmental challenges requires bold thinking and collaboration, and this partnership is a fantastic opportunity to lead the way in creating sustainable, industry-wide solutions. By combining cutting-edge research with Bupa青瓜视频檚 real-world expertise, we can drive meaningful change that reduces the healthcare sector青瓜视频檚 impact on the planet while maintaining the highest clinical standards. This is a vital step forward in our journey to help create a greener, healthier future.青瓜视频�

This new partnership has been recognised by the Engineering & Physical Sciences Research Council (EPSRC) for bringing together The University of Manchester青瓜视频檚 interdisciplinary collaborative researchers and knowledge-base, with data from and access to more than 500 Bupa dental practices, clinics, care homes and The Cromwell Hospital. The necessity of tackling these challenges was highlighted by The University青瓜视频檚 research platform and Bupa. These are challenges which can only be tackled by marrying academia and industry.

This new collaboration was kick-started by , The University of Manchester青瓜视频檚 recently announced innovation capability tasked with supercharging the region青瓜视频檚 innovation ecosystem. Unit M is now live and actively engaging with entrepreneurs, investors, and changemakers eager to shape the future of the region.

Professor Lou Cordwell, CEO of Unit M said: 青瓜视频淎head of the formal launch of Unit M, the founding leadership team has been working to develop this partnership with Bupa to highlight the benefits of organisations engaging with Unit M to drive real-world impact and innovation. The collaboration has taken shape over the past two years to establish a long term, University wide innovation partnership.青瓜视频�

The new collaboration builds on the shared commitment of both the University and Bupa to the region. Last month, The University of Manchester reaffirmed its status as a global leader in sustainability by retaining its position in the top 10 worldwide in the . Meanwhile, Bupa was one of the first healthcare companies to set science-based CO2 reduction targets and an ambitious 2040 net zero pathway.

Find out more about Unit M:

Just like the proteins in our muscles, which convert chemical energy into power to allow us to perform daily tasks, these tiny rotary motors use chemical energy to generate force, store energy, and perform tasks in a similar way.

The finding, from The University of Manchester and the University of Strasbourg, published in the journal provides new insights into the fundamental processes that drive life at the molecular level and could open doors for applications in medicine, energy storage, and nanotechnology.

The artificial rotary motors are incredibly tiny青瓜视频攎uch smaller than a strand of human hair. They are embedded into polymer chains of a synthetic gel and when fuelled, they work like miniature car engines, converting the fuel into waste products, while using the energy to rotate the motor.

The rotation twists the gel青瓜视频檚 molecular chains, causing the gel to shrink, storing the energy, much like winding like an elastic band. The stored energy can then be released to perform tasks.

So far, the scientists have demonstrated the motor青瓜视频檚 ability to open and close micron-sized holes and speed up chemical reactions.

Professor Leigh added: 青瓜视频淢imicking the chemical energy-powered systems found in nature not only helps our understanding of life but could open the door to revolutionary advances in medicine, energy and nanotechnology.青瓜视频�

]]>Formed to challenge and disrupt the global conveyor belt market, Ecobelt Ltd is an environmentally ambitious company that champions environmental sustainability and fosters a circular life-cycle approach for belting use.

In the UK alone, 4,000 tonnes of conveyor belts are incinerated or sent to landfill every week.

The 青瓜视频楽ustainable Materials Innovation for Net-zero青瓜视频� award recognises Ecobelt青瓜视频檚 patented innovative belt splice technology to address the main cause of belt failure. The technology extends belt lifespan from months to years, therefore improving the upstream sustainability by reducing the demand for new belts.

Through partnership and collaboration with The University of Manchester青瓜视频攕upported by its UKRI Impact Acceleration Account and the Sustainable Materials Innovation Hub at the Henry Royce Institute青瓜视频擡cobelt tested the performance of their technology to develop an approach to repair damaged conveyor belts, employing a whole life-cycle environmental impact approach.

The judges from the Institute of Materials, Minerals & Mining commended Ecobelt青瓜视频檚 technology, citing the robust research base and collaboration with partners as key indicators to Ecobelt青瓜视频檚 commitment to environmental sustainability.

Conveyor belts service virtually all consumer products, production and manufacturing facilities globally, driving a market valued at $6 billion (USD) annually, fuelled by e-commerce and industry 4.0.

Despite this, the industry has been remarkably stagnant in relation to innovation, sustainability and the manufacturing process of materials used in conveyor belts. As conveyor belts are fossil fuel based, manufacturing consumes huge natural resources whilst producing significant Greenhouse Gases 青瓜视频� an issue that Ecobelt seeks to change.

Whilst Ecobelt青瓜视频檚 next steps for commercial scale up are still unfolding, the technology青瓜视频檚 potential for lasting impact in the industrial settings are clear.

Professor Michael Shaver, Director of the Sustainable Materials Innovation Hub said: 青瓜视频淥ur world is driven 青瓜视频� both literally and figuratively 青瓜视频� by conveyor belts. Yet we don青瓜视频檛 think of them as essential in championing Manchester as a sustainable city.

青瓜视频淥ur eyes have been opened by this hidden gem of a local business: Ecobelt have tackled an invisible material flow that is essential to keeping our manufacturing and delivery systems moving by improving material repair, reuse and circularity. It has been a privilege to work on assessing the AnnStuMax technology and quantifying its impressive environmental credentials.青瓜视频�

]]>The study, led by scientists at The University of Manchester, has revealed that a material known as a metal-organic framework (MOF) - an ultra-porous material - can be modified to capture and filter out significantly more benzene from the atmosphere than current materials in use.

Benzene is primarily used as an industrial solvent and in the production of various chemicals, plastics, and synthetic fibres, but can also be released into the atmosphere through petrol stations, exhaust fumes and cigarette smoke. Despite its widespread applications, benzene is classified as a human carcinogen, and exposure can lead to serious health effects, making careful management and regulation essential.

The research, published in the journal today, could lead to significant improvements in air quality both indoors and outdoors.

MOFs are advanced materials that combine metal centres and organic molecules to create porous structures. They have a highly adjustable internal structure, making them particularly promising for filtering out harmful gases from the air.

The researchers modified the MOF structure 青瓜视频� known as MIL-125 青瓜视频� by incorporating single atoms from different elements, including zinc, iron, cobalt, nickel and copper to test which would most effectively capture benzene.

They discovered that adding a single zinc atom to the structure significantly enhanced the material青瓜视频檚 efficiency, enabling it to capture benzene even at ultra-low concentrations 青瓜视频� measured at parts per million (ppm) 青瓜视频� a significant improvement over current materials.

The new material 青瓜视频� now known as MIL-125-Zn 青瓜视频� demonstrates a benzene uptake of 7.63 mmol per gram of material, which is significantly higher than previously reported materials.

It is also highly stable even when exposed to moisture, maintaining its ability to filter benzene for long periods without losing effectiveness. Tests show that it can continue removing benzene from air even under humid conditions.

As the research progresses, the team will look to collaborate with industry partners to develop this and related new materials, with the potential of integrating it into ready-made devices, such as air purification systems in homes, workplaces, and industrial settings.

]]>Plastics play a crucial role in healthcare, but the current linear model of using and then incinerating leads to significant waste and environmental harm. Through a Knowledge Transfer Partnership (KTP), materials experts at Manchester will work in collaboration with Vernacare 青瓜视频� specialist manufacturers of infection prevention solutions 青瓜视频� to investigate how the sustainability of plastics can be improved through the creation of more circular products from waste polypropylene (PP) and polycarbonate (PC).

A 24-month project, led by an interdisciplinary team from The University of Manchester and Vernacare, aims to create new insight into the behaviour of real-world polypropylene and polycarbonate products during mechanical recycling. The team will be led by experts including Dr Tom McDonald, Dr Rosa Cuellar Franca, Professor Mike Shaver, Simon Hogg, and Dr Amir Bolouri. It also will advance knowledge on the selection, characterisation and use of plastic to optimise recyclability, while developing understanding of the complex environmental impacts of product design and supply chain.

Finally, life cycle assessment will be used to evaluate the sustainability for different approaches to the circularity of these plastics. This project will involve the knowledge transfer of the academic team青瓜视频檚 expertise in plastics recycling, plastics circularity and rigorous life cycle assessment.

Alex Hodges, CEO of Vernacare, explained: 青瓜视频淭hrough this project we aim to change how plastics are viewed and used in healthcare. Our work with Manchester will ensure we青瓜视频檙e at the forefront in sustainable single use healthcare product research. It will enable us to embed product lifecycle, environment assessment capability and materials research and development into our business culture so that we青瓜视频檙e in pole position, able to lead the market in the development and testing of future solutions. It will also help Vernacare economically, by offsetting a portion of our 青瓜视频7m annual polypropylene costs while also broadening their appeal to eco-conscious customers.青瓜视频�

The research will be conducted through the (SMI Hub), a cutting-edge facility dedicated to sustainable plastic solutions. The SMI Hub is part of the Henry Royce Institute at The University of Manchester and is partly funded by the European Regional Development Fund.

Innovate UK青瓜视频檚 Knowledge Transfer Partnerships funding support innovation by matching businesses with world-leading research and technology. Projects are focused on delivering a strategic step change in productivity, market share and operating process by embedding new knowledge and capabilities within an organisation. Delivered through the Knowledge Exchange Partnerships team, part of Business Engagement and Knowledge Exchange, The University of Manchester has collaborated on more than 300 KTPs and in the last five years alone, has supported 42 KTPs with a total research value of 青瓜视频11 million.

By working together, The University of Manchester and Vernacare aim to lead the way in sustainable healthcare products, ensuring a healthier planet for future generations.

]]>Alzheimer's is marked by a loss of brain cells, whereas glioblastoma is responsible for rapid cell growth. The unexpected relationship between the two, known as 青瓜视频榠nverse comorbidity青瓜视频�, suggests that there might be a deeper biological connection we don青瓜视频檛 yet understand. If we could work out what that connection is, we might be able to design vital new treatments.

Now, a Manchester team are on a mission to discover the answer and make a positive difference, through what they青瓜视频檝e called the NanoNeuroOmics Project.

The challenge they face

Both Alzheimer's disease and glioblastoma are often quite well-advanced in a person, by the time they青瓜视频檙e diagnosed. The current methods we use for this, such as PET or MRI scans, still aren青瓜视频檛 very effective at early detection. What we really need are simple blood tests that can spot changes early on.

In both conditions, the blood-brain barrier (which normally protects our brain), becomes more permeable 青瓜视频� meaning it青瓜视频檚 possible to detect disease-related molecules in the blood. This could in turn help us to identify people who were more at risk, and to monitor responses to different types of treatment.

However, it won青瓜视频檛 be easy. In current blood tests, when we青瓜视频檙e looking for certain proteins 青瓜视频� key indicators of disease 青瓜视频� they青瓜视频檙e often drowned out by a range of other proteins. Developing a way to spot those blood-based 青瓜视频榖iomarkers青瓜视频� for brain health, which can easily be used in clinical practice, would be a key next step.

How Manchester innovation could make a difference

By merging expertise in nanotechnology, protein analysis, and blood biomarker discovery, the NanoOmics lab are aiming to:

- Identify new blood proteins(biomarkers) that could help in the early diagnosis and monitoring of the Alzheimer's and glioblastoma.

- To understand more about the link that Alzheimer's and glioblastoma share.

The NanoOmics lab is looking to identify these unique biomarkers by tracking protein changes in blood and the brain over time, and across different stages of both diseases. They will use nanotechnology to detect these 'protein markers,' employing nanoparticles to isolate them from the multitude of other molecules present in the blood. With their 青瓜视频楴anoomics青瓜视频� technology, these nanoparticles capture disease-related molecules, acting almost like tiny 青瓜视频檉ishing nets青瓜视频�. Using this approach, the team can filter out a huge number of other proteins that are currently getting in the way. In turn, by analysing what they青瓜视频檝e captured, our researchers are aiming to identify new biomarkers that are currently undetectable by state-of-the art protein analysis approaches.

Hope for the future

To achieve this, Group Leader Dr Marilena Hadjidemetriou and her NanoOmics team have been combining long-term studies in lab models, with validation studies using biofluids obtained from human patients.

The aim isn青瓜视频檛 only to search for new blood biomarkers, but to gain further insight into how neurological conditions work, so that we can connect changes we see in our blood with changes that can happen in our brain.

Their approach is multidisciplinary, working with experts across both nanotechnology and omics sciences, to improve early disease detection and hopefully develop personalised treatment for future patients.

NanoNeuroOmics represents a significant step forward in the quest to understand, detect and treat complex neurological diseases.

About Dr Marilena Hadjidemetriou

Dr Hadjidemetriou is the NanoOmics Group Leader, and a Lecturer in Nanomedicine in Manchester青瓜视频檚 School of Biological Sciences.

She joined the Nanomedicine Lab at the University of Manchester as a Marie Curie Early-Stage Fellow and full-time PhD student, working on the development of the nanoparticle protein corona as a tool for cancer diagnostics.

After her PhD, Dr Hadjidemetriou was granted a postdoctoral fellowship by the Medical Research Council, to focus on the discovery of novel biomarkers in Alzheimer青瓜视频檚 disease. She was also awarded a Manchester Molecular Pathology Innovation Centre Pump Priming Grant and the CRUK Pioneer Award, to work on the nanoparticle-enabled discovery of blood biomarkers for a variety of pathologies.

Now leading the NanoOmics lab Dr Hadjidemetriou is aiming to develop nanotechnology platforms that explore disease pathways and uncover molecular biomarkers.

Dr Hadjidemetriou青瓜视频檚 recent research includes:

To discuss this research, contact Dr Marilena Hadjidemetriou at marilena.hadjidemetriou@manchester.ac.uk

Paint - an economically and environmentally critical material

In the UK, over 10,000 people work in the coatings industry, which contributes over 青瓜视频11 billion to the economy, and supports the manufacturing and construction sectors worth around 青瓜视频150 billion.

Corrosion damage costs the UK 2-3% of its Gross National Product each year (about 青瓜视频60 billion in 2016). Protective coatings like paints help prevent corrosion but are complex to formulate, meaning new product developments is slow.

With a growing demand for sustainable materials that extend the lifespan of infrastructure like wind turbines, it's crucial to understand how these coatings work to get new, better performing and more sustainable products to market.

Manchester青瓜视频檚 corrosion research expertise

AkzoNobel and The University of Manchester are collaborating to address this through their research.

Claudio Di Lullo, Manager of AkzoNobel青瓜视频檚 Substrate Protection Expertise Centre, explains: 青瓜视频淎bout 12 years ago, we set up a partnership with The University of Manchester because we recognise that corrosion is one of the big challenges we have to face. We make paint, we develop paint. We understand the practical applications and what青瓜视频檚 needed to make it perform.

青瓜视频淲hat the University brings is the ability to characterise, analyse and understand some of the mechanisms. They can do deeper science that青瓜视频檚 an essential part of understanding what青瓜视频檚 going on. We get fresh insights that will help us to develop the next generation of paint.青瓜视频�

Understanding the fundamentals of how paint works

Building on this partnership, Manchester and AzkoNobel developed 青瓜视频楽ustainable Coatings by Rational Design青瓜视频� (SusCoRD), a five-year interdisciplinary EPSRC Prosperity Partnership, that brings together a critical mass of expertise 青瓜视频� spanning academic knowledge from the universities of Manchester, Sheffield, and Liverpool capabilities 青瓜视频� to understand how paint works.

In an industry-first, the partnership looked to match a detailed scientific understanding of the mechanisms of coatings failure with state-of-the-art machine learning. The aim was to deliver a framework for developing more sustainable protective coatings and nanocomposite materials using digital design. This would help enable industry to replace the current trial-and-error and test new, sustainable materials, accelerating the formulation of new products.

Uniting corrosion science with machine learning

Working across four specific workstreams, the teams drove discoveries across two main areas:

analysis characterisation of coatings in the substrate, the polymer and interfaces; and digital technology, specifically predictive approaches, modelling and simulation, with the aim to ultimately producing digital twins.

Manchester led on corrosion protection, with Sheffield and Liverpool focusing on polymer interface and machine learning, respectively. Their work focuses on:

- Predictive Design and Testing: By undertaking a review of AkzoNobel青瓜视频檚 historic corrosion test data, researchers were able to find the best formulations for corrosion protection. Applying machine learning models, they were then able predict and optimise these formulations, creating models that could successfully identify new, effective combinations. To support this, complementary tools were developed to automatically interpret electrochemical data, improving accuracy and efficiency.

- Polymers and interfaces: The team studied how small molecules like water and solvents interact with polymer surfaces with Manchester leading on advanced microscopy, to explore how polymers and metals bond. Key results included the discovery that that metal-polymer binding has a much larger influence in measurements than previously thought 青瓜视频� a critical insight in the drive to create more high-performance, eco-friendly high solid and water-borne coating systems.

- Coatings and substrates: Using a combination of analytical electron microscopy and X-Ray CT, researchers were able to characterise the microstructural evolution in polyester powder coating, revealing different stages in the degradation process. By identifying and mitigating microstructural weak points, finding ways to control microstructure 青瓜视频� which previously reduced the efficacy of coatings 青瓜视频�, and by understanding the key properties affecting performance, the researchers have advanced insight to inform the way durable coatings are formulated.

- Simulation and modelling: . By creating and studying digital models, the team was able to interrogate experimental results and test hypothesis when physical experiments were unable to provide relevant information. These models created ranged from atomic-level analsyis of the polymer/substrate interface, to understanding how a flaw in the coating impacts an electrochemical cell.

Creating the sustainable paints of the future

The findings of the five-year project can now be used to inform higher-technology readiness level research, which in turn will help unlock ways to making more sustainable paint.

Claudio Di Lullo explains: 青瓜视频淎t AkzoNobel, we recognise our paint has a carbon footprint contribution and we've set the ambitious target in 2030 of having a 50% reduction in the carbon footprint across the whole value chain.

青瓜视频淭he potential impacts of this project, for us as a company are to produce new generation products that perform better and are more sustainable, and for us to do it quicker. Machine learning gives us the angle to accelerate our new product development.青瓜视频�

Professor Stuart Lyon, from The University of Manchester adds: 青瓜视频淭here are two aspects of sustainability. The manufacture of the paint needs to be sustainable, but also its materials need to be sustainable. And that essentially means making it last longer, so we don青瓜视频檛 have to repaint assets like wind turbines, mid-life, which is hugely expensive.

青瓜视频淭he work we青瓜视频檝e done so far has involved using all these analytical tools to explore the science behind how paint works and to create opportunities to make paints differently. The next stage is to use that information to develop tools that make paint in different ways, using different materials, which are perhaps more sustainable 青瓜视频� which last longer, which create assets that have a much greater lifetime.青瓜视频�

For more information visit the

To discuss this project further, or to explore future collaboration contact Xiaorong Zhou, Professor of Corrosion Science and Engineering or Dr Jane Deakin, SusCoRD project manager.

Related papers:

- Manipulating transport paths of inhibitor pigments in organic coating by addition of other pigments.

Prosperity Partnerships

Prosperity Partnerships are collaborative research programmes funded jointly by businesses and the UK government through the Engineering and Physical Sciences Research Council (EPSRC) and other UKRI councils.

Prosperity Partnerships are an opportunity for businesses and their existing academic partners to co-create and co-deliver a business-led programme of research activity arising from a clear industrial need.

To explore a Prosperity Partnership with Manchester, contact our Business Engagement team at collaborate@manchester.ac.uk

A leading nanomedicine researcher at The University of Manchester has secured a 鈧�1.5m (青瓜视频1.3m) European Research Council (ERC) Starting Grant to push forward pioneering research on Alzheimer青瓜视频檚 disease and glioblastoma.

The five-year project, NanoNeuroOmics, aims to combine breakthroughs in nanotechnology, protein analysis, and blood biomarker discovery to make advances in two key areas.

First, the team led by will explore the use of nanoparticles to enrich and isolate brain-disease specific protein biomarkers in blood. These discoveries could pave the way for simple, reliable blood tests that diagnose Alzheimer青瓜视频檚 and glioblastoma in their early stages.

Second, the research will investigate the phenomenon of 青瓜视频渋nverse comorbidity,青瓜视频� which suggests that having one of these conditions may reduce the risk of developing the other. Dr. Hadjidemetriou and her team will explore this surprising relationship to uncover any deeper biological connection that could lead to new treatment pathways.

Building on her 2021 research, where Dr. Hadjidemetriou developed a nanoparticle-enabled technology to detect early signs of neurodegeneration in blood, this project has the potential to transform how these brain diseases are diagnosed and treated.

Dr. Hadjidemetriou青瓜视频檚 previous work involved using nano-sized particles, known as liposomes, to "fish" disease-specific proteins from the blood. This breakthrough enabled her team to discover proteins directly linked to neurodegeneration processes in the brain, among thousands of other blood-circulating molecules. In animal models of Alzheimer青瓜视频檚, this nano-tool successfully captured hundreds of neurodegeneration-associated proteins. Once retrieved from the bloodstream, the molecular signatures on the surface of these proteins were analysed, offering a clearer picture of the disease at a molecular level.

Now, Dr. Hadjidemetriou's team will evolve this expertise to identify highly specific biomarkers by tracking protein changes in both blood and brain over time and across different stages of Alzheimer's and glioblastoma. By working with different nanomaterials, they hope to isolate these key protein markers from the complex mix of molecules in the blood.

The NanoNeuroOmics project青瓜视频檚 multidisciplinary approach brings together experts in nanotechnology and omics sciences to develop methods for detecting and potentially treating these diseases with greater precision. Research will be conducted at The University of Manchester青瓜视频檚 , a cutting-edge facility dedicated to advancing nanoscale technologies. The Centre's focus spans multiple fields, including omics, neurology, therapeutics, and materials science.

Dr. Hadjidemetriou青瓜视频檚 team is also part of Manchester青瓜视频檚 vibrant 2D materials science community, home to the discovery of graphene 20 years ago, continuing the university青瓜视频檚 legacy of scientific innovation.

]]>Lithium-ion batteries, which power everything from smartphones and laptops to electric vehicles, store energy through a process known as ion intercalation. This involves lithium ions slipping between layers of graphite - a material traditionally used in battery anodes, when a battery is charged. The more lithium ions that can be inserted and later extracted, the more energy the battery can store and release. While this process is well-known, the microscopic details have remained unclear. The Manchester team青瓜视频檚 discovery sheds new light on these details by focusing on bilayer graphene, the smallest possible battery anode material, consisting of just two atomic layers of carbon.

In their experiments, the researchers replaced the typical graphite anode with bilayer graphene and observed the behaviour of lithium ions during the intercalation process. Surprisingly, they found that lithium ions do not intercalate between the two layers all at once or in a random fashion. Instead, the process unfolds in four distinct stages, with lithium ions arranging themselves in an orderly manner at each stage. Each stage involves the formation of increasingly dense hexagonal lattices of lithium ions.

, who led the research team, commented, "the discovery of 'in-plane staging' was completely unexpected. It revealed a much greater level of cooperation between the lattice of lithium ions and the crystal lattice of graphene than previously thought. This understanding of the intercalation process at the atomic level opens up new avenues for optimising lithium-ion batteries and possibly exploring new materials for enhanced energy storage."

The study also revealed that bilayer graphene, while offering new insights, has a lower lithium storage capacity compared to traditional graphite. This is due to a less effective screening of interactions between positively charged lithium ions, leading to stronger repulsion and causing the ions to remain further apart. While this suggests that bilayer graphene may not offer higher storage capacity than bulk graphite, the discovery of its unique intercalation process is a key step forward. It also hints at the potential use of atomically thin metals to enhance the screening effect and possibly improve storage capacity in the future.

This pioneering research not only deepens our understanding of lithium-ion intercalation but also lays the groundwork for the development of more efficient and sustainable energy storage solutions. As the demand for better batteries continues to grow, the findings in this research could play a key role in shaping the next generation of energy storage technologies.

The (NGI) is a world-leading graphene and 2D material centre, focussed on fundamental research. Based at The University of Manchester, where graphene was first isolated in 2004 by Professors Sir Andre Geim and Sir Kostya Novoselov, it is home to leaders in their field 青瓜视频� a community of research specialists delivering transformative discovery. This expertise is matched by 青瓜视频13m leading-edge facilities, such as the largest class 5 and 6 cleanrooms in global academia, which gives the NGI the capabilities to advance underpinning industrial applications in key areas including: composites, functional membranes, energy, membranes for green hydrogen, ultra-high vacuum 2D materials, nanomedicine, 2D based printed electronics, and characterisation.